Turntable Test

Acoustic Signature Hurricane Neo Review

In the eye of the hurricane, utmost peace and quiet are known to be found. With the Hurricane Neo from Acoustic Signature, we encountered a turntable whose bulletproof housing shrugs off any onslaught. The true refinement, however, lies in its bright solutions.

You don‘t really want to say it, but the Covid pandemic with its forced lockdowns and time-outs also had a few good aspects for the hi-fi industry. This was the case for the team around Gunther Frohnhöfer, head of Acoustic Signature, to name one example. They used the pause to completely renew the considerable repertoire of turntables and tonearms the southern German specialist offers, with hardly anything remaining unchanged.

The company, which is located in the Swabian town of Süßen and thus in a kind of epicenter of German engineering, can master such challenges because they manufacture most of the required parts themselves – from the bulky aluminum chassis to the filigree tonearm axle – and focus on highest precision. The motto "Teutonic Engineering" is found on the front door of the industrious company, standing for solid "mass" and class at the same time.

The first representative of the new line, the entry-level Maximus Neo, was reviewd by us here. It competed equipped with the smallest tonearm plus the MCX-2 MC pickup and impressed not only with its flawless finish, but also with first-class sound quality.

Dual-Motor-Drive

All of this left us hungry for more, which is why the good 30 kilograms of the Hurricane Neo now rest on our shelf – a feast for the eyes in the shape of a turntable located somewhere between mechanical fascination and puristic pragmatism. And you can indeed see the weight: The turntable chassis, which is made of solid aluminum blocks and offers room for up to three tonearms, stands wide-legged on three mighty, gel-damped outrigger feet. These can be adjusted in height via their large metal frames, and each one has a small ball on the underside to ensure a defined contact with the base.

There is enough space to slide the also solidly built control panel halfway under the frame so that only the two buttons for on/off and the two speeds peek out. Of course, you can also place it somewhere else if you desire. The LAN cable that keeps the box in contact with the external power supply and control unit is long. The same goes for the cable that leads from the DMC-10 – as the microprocessor-controlled power station is named – to the turntable itself.

In this unit, an encapsulated switching power supply provides the juice for the high-precision, quartz-based and digitally generated sine waves for the two AC synchronous motors, which drive the subplatter from opposing points. On the one hand, tiny individual errors are leveled out and – possibly even more important – the one-sided pull on the platter axle and thus an imbalance in the lateral load is avoided. Both aspects serve to benefit the smoothness of the turntable.

"Silencers" at Work

A highlight of the DMC-10, however, is the "Automatic Vibration Control", or AVC for short. This automatically compensates for the slightest deviations in the structure of the coils and their plates. Due to the production process, these are never exactly at a 90-degree angle to each other, which is noticeable through slight vibrations in the operation and "ripples" in the DC voltage. The AVC system detects these about every five minutes and then effectively counteracts through minimal phase shifts. If the speed is not perfect, tiny buttons on the back allow for extremely sensitive corrections.

Let‘s look on the mechanical side of the vibration control: A "Constraint Layer Damping" (CLD) technology is found within the chassis in the form of a steadying silicone sheet placed between the two solid parts of the chassis. The "silencers" are of course also part of that, their upper ends visible in the almost ten-kilogram platter, which in turn is damped on its underside with a mat of carbon and leather..

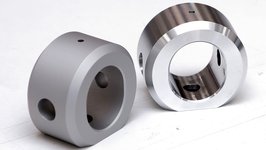

These "silencers" are small brass cylinders that are press-fitted into the aluminum platter. Rubber rings keep the materials distanced from each other. While the platter vibrates audibly when stimulated without them, it is absolutely silent after they are inserted – except for a short "thump" –, as Frohnhöfer demonstrated on two otherwise identical platters. Eight of these cylinders are to be found in the Hurricane Neo.

For the tonearm, we chose the TA-2000 Neo in a nine-inch version from the diverse range the swabians have on offer. On its own, it costs around 3000 euros and thus stems from the highest league and also matches the turntable‘s appearance perfectly thanks to its solid bearing housing. Its stiff and hard tube is designed in "Dual Layer" technology with two layers placed inside each other. The low-friction, zero-backlash ball bearings are sourced from the specialist SKF, the internal cabling from Mogami – another first-class name.

The arm can be mounted on SME or Rega bases, is adjustable in any direction and is also available as a twelve-inch version. Its anti-skating value is set via a flexible rod and the headshell can be moved freely. Thanks to the included template, adjusting the arm and cartridge system poses no problems. Setting the tracking force, however, requires a tonearm scale. Afterwards, the scaleless counterweight is fixed immovably with grub screws.

While we usually have to recommend quickly replacing the phono cables included with turntables, the Hurricane Neo represents a commendable exception. Its cable is an Audioquest "Wildcat" that also meets higher demands, as cross-checks with some compararable models quickly proved.

Even the MC pickup we tested in conjunction with it comes from the Acoustic Signature collection. Except for its filigree metal housing, the MCX-3, which costs just under 1350 euros, is obviously not manufactured by the company itself. It is built according to Frohnhöfer‘s wishes by the distinguished Danish manufacturer Ortofon and is based on their "Quintet" line. The MCX-3 offers a multi-faceted "Fine Line" diamond that is supposed to capture maximum information from the groove.

The Calm in the Storm

Assembling the Hurricane Neo turned out to be inspiringly delightful. Not only did all components impress with their flawless surfaces and manufacturing quality – everything also fit together perfectly. Anyone who has a bit of knowledge on the subject will greatly enjoy it. Of course, the Acoustic Signature is not intended as a three-dimensional puzzle for analog enthusiasts – although it is certainly suited for that – but to present records impressively. No doubt: The Hurricane Neo takes every heart, well, by storm.

But only when the music gets turbulent. The massive turntable itself impresses with composure and serenity. It neither shows any nervousness, nor does it let itself be stimulated to do so by rapid rhythms on his platter or by heavy structure-borne noise, i.e. loud speakers in the immediate vicinity.

A benchmark for high class and finesse is the amount of space, airiness and sparkling flair present in the sound image; these are essential for a natural musical experience and are missing if the turntable swallows up the necessary fine details. You don‘t need to worry about the Acoustic Signature in this regard: Not only Diana Krall‘s "Live In Paris" album, bursting with esprit, was presented with a wide spatial spectrum and exemplary staggering in every direction, with plenty of air between the different actors – as well as an organized overview of the complex events which only the best devices can convey. The impression of dignified sovereignty was established immediately. Even during the dazzling orchestral passages of Chadwick‘s "Jubilee" suite, the Hurricane Neo was the calm in the storm and solid as a rock.

Lovers of large orchestral works with sweeping melodic arcs, sonorous coloration and a load of low-frequency energy will especially appreciate the slightly softened diction the MCX-3 carries in the upper frequencies. Additionally, it also sets hardly any limits to the spatial development of the performance. Thanks to its first-class resolving skills, it never seems obstructed, actually just right for distinctly present pop records. In the fulminant bass of James Taylor‘s crisp "Her Town Too", it however seemed a few nuances too full and round. Overall, this in-house MC thus remains slightly below the highest level offered by the turntable and tonearm.

In order to check what is possible and reasonable, we mounted other MC cartridges from our test collection onto the TA-2000. Some of these admittedly cost twice as much as the charming MCX-3 – but their price compared to the other components seemed to us all the more reasonable. And there you have it: With these, the bar was raised even higher in terms of finesse and "relentlessness" in the definition of which the drive and arm are capable of. Thus equipped, the now uncompromising Hurricane Neo even became a candidate for the very highest reference honors.

Anyone who experiences how richly shaded the German can fan out dark clouds of sound from the lowest frequency depths understands the importance of this quality for the liveliness and nobility of the overall performance. When these gather into a menacing storm of sound, it is not a threat to the Hurricane Neo, in which material effort meets cleverness; but a welcome challenge. Because it shows itself to be well-prepared in every respect.

Verdict

A turntable like a rock. The Hurricane Neo, which is as solidly as it is precisely manufactured, impresses all around with finesse in mechanics and workmanship. With a suitable high-end cartridge on an equally refined tonearm, it easily plays in the reference class thanks to its unshakable performance, refined down to the smallest detail. Not cheap, but aims to provide pleasure for an eternity.

Technical Details

Turntable

Acoustic Signature Hurricane Neo

Price: ca. 12000 € (Last check: 30.11.2021)

Dimensions WxHxD: 45 x 21 x 42 cm

Weight: 31.5 kg

Warranty: 15 years (/Tonarm: 5 Jahre)

Manufacturer: AS Distribution

General Data

Measurement Results

Measurement Values

| Pickup type: | MC |

| Needle flexibility: | 15 µm/mN |

| Output voltage (1 kHz, 5 cm/sec): | 0.46 mV |

| Recommended contact force: | 23 mN |

Stereo Test

Sound Level Turntable: 100%

Price/Performance

Lab Comment

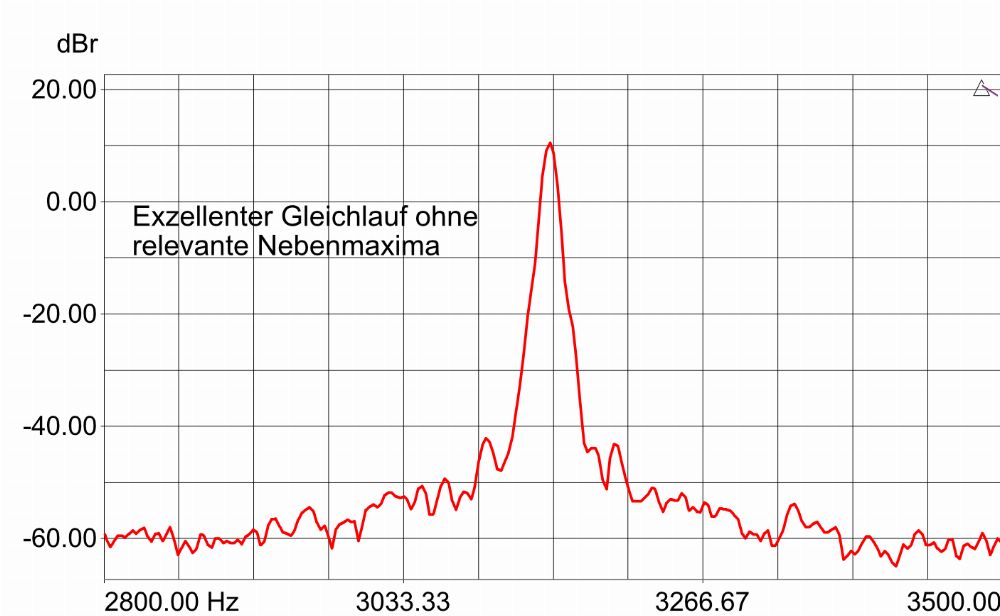

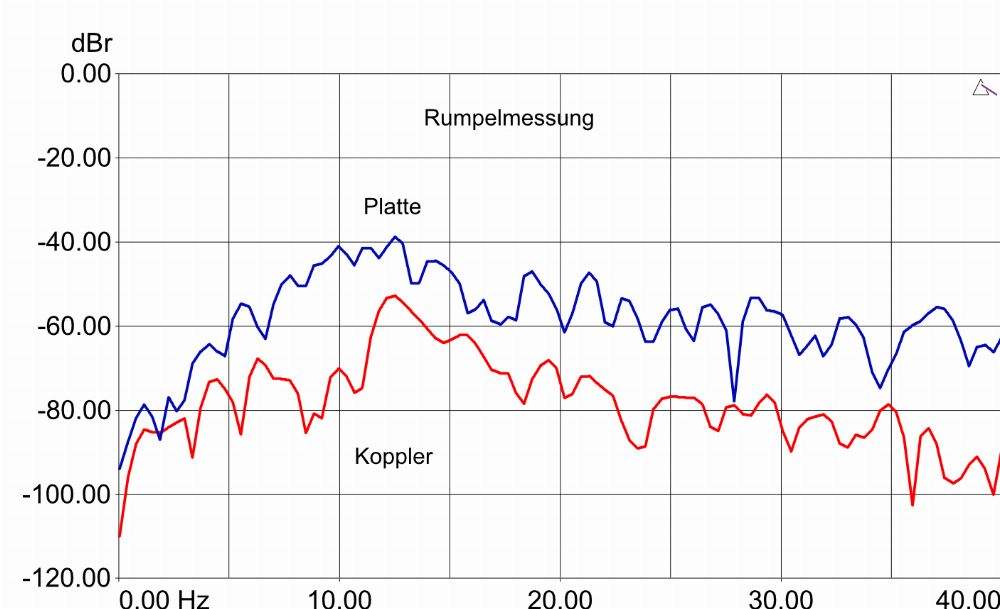

First-class values for synchronization and rumble, with the latter improving even more when using the measuring coupler, which excludes influences from the measuring record (red line). Thanks to the fine adjustment in microsteps, the speeds can be individually calibrated perfectly.

Features

Dual-motor drive, external power supply and control unit DMC-10, fine speed control, height-adjustable feet, precise adjustment template for tonearm and cartridge

Test Devices

Turntables:

Clearaudio Reference Jubilee,

Transrotor Rondino nero / TRA9/2.1

Cartridges:

EMT JSD Pure Black,

Ortofon Verismo,

Transrotor Figaro,

Vertere Mystic

Phono preamos:

Brinkmann Edison MkII,

Nagra Classic Phono

Pre-/power amps:

Accustic Arts Preamp III/ AmpII-MK4

Loudspeakers:

B&W 801 D4,

Dynaudio Confidence 50

Cables:

Boaacoustic Silver Galaxy (Phono),

HMS Suprema (AF),

In-Akustik LS-2404 (Bi-Wire),

Boaacoustic Black.sonic-25 (Single-Wire)

"If you want it to be right, do it yourself!"

"If you want it to be right, do it yourself!"

From planning to the finished product, Acoustic Signature can do virtually everything in-house. This is, of course, backed by state-of-the-art, digital CAD development, with which every component is precisely defined. While some competitors are proud to call a CNC machine their own, the Swabians have nine of them up and running. None is more than five years old, says Gunther Frohnhöfer, so that they are not "worn out", but rather always up to date and absolutely precise. The reason for this thorough "homemade" style is to be found in repeated trouble with suppliers regarding quality as well as delays due to the eternal back and forth of deliveries, complaints and new deliveries, which add up again and again....

Their uncompromising standard is known within the industry, which is why Acoustic Signature manufactures a lot of turntables for other companies in addition to its own players, tonearms and more. Mark Levinson‘s high-end No.5105 comes from Süßen, for example. Other brands prefer not to be named. A total of around 2,500 turntables leave the busy factory each year, where the fascination of mechanics can be experienced in both its coarsest and finest aspects. The former, when you watch through the window of a CNC milling machine as it models a turntable chassis out of an aluminum block; but the most filigree parts are also created there, such as the bearing housing of the 2000 tonearm , which– after blasting and anodizing – reaches the assembly table for further processing. Practically everything is assembled by hand by specialized employees who have been with the company for years and know exactly what they are doing. "Our complaint rate is close to zero," reports Frohnhöfer proudly. Which it should be, because the export share of around 90 percent is very high. "That means that every problem is about 10,000 kilometers away, so it can‘t be fixed quickly", the boss points out. "That would cost money, time and nerves. It‘s better to have everything be correct right away."

Turning such a large wheel demands precise logistics. For each product, a detailed production protocol is present, which specifies the entire manufacturing process step by step and must be executed exactly according to plan. Therein, it is also noted which parts are necessary and where they can be found. Thus, there are literally more than 5000 meticulously labeled blue plastic slipcases and several hundred cardboard boxes, so that no one has to spend a long time searching.

For inscribing chassis and other parts, they have their own LED color screen printer that produces crisp, durable letters and logos. We were able to observe as it raced across an otherwise finished chassis at lightning speed, leaving its mark.

The optical measuring device costing around 80,000 euros, which determines the parameters of almost any workpiece fully automatically, is absolutely fascinating. It is used to check incoming goods, as well as many parts in the midst of production, for compliance with the strict tolerances. Frohnhöfer inserts an arm axle, starts up a program, and a few seconds later all the measured values plus a graphic display appear on the screen. "We don‘t just claim to be accurate to one thousandth of a millimeter," the quality fanatic is delighted to say, "we can also prove it." Extremely important for the man who prefers to get it right and therefore does it himself.

MAGAZINE

MAGAZINE